RÁBA Automotive Holding Plc..

9027 Győr, Martin út 1.

Company registration number: Cg. 08-10-001532

Tax number: 11120133-2-51

Telephone: +36 30 444 9500

E-mail: raba@raba.hu

Rába grants

NBT - Corporate Investment Support Program

Already in 2016, the General Assembly of Rába approved a significant technology development and capacity expansion investment program for the Undercarriage business. The aim of the development is to modernize the production technology of key products and to increase emissions while improving efficiency and quality.

To help finance the developments, the company supplemented the above program with its other two business lines, into a total of approximately HUF 12.4 billion worth of projects and submitted a successful application for the investment support program for large companies announced by the Goverment. The amount of support received varies from one subsidiary to another and from one site to another, between 25 and 35%, and is approximately HUF 3.2 billioin at the gruop level.

In addition to the modernization of technology, the program also includes related infrastructure, logistics and tooling developments. As a first step in implementation, contracts were signed to procure the necessary equipment and resources.

During the technology development and capacity expansion investment program, Rába's market share and role in the global automotive industry will be further strengthened. With the completion of the developments, it is planned that every second or third European truck will roll off assembly lines with a front axle manufactured at Rába.

Rába Axle CO. Ltd.

Objective of aid: Forging technology development and capacity expansion investment program

Eligible cost: HUF 9,729,209,444

Amount of support: HUF 2,431,858,793

Aid intensity or amount: 25%

Location of the program: 9027 Győr, Martin utca 1 hrsz.: 5454/7, 5454/8, 5454/9.

Rába Vehicle Ltd.

Objective of support: Technology development investment program at Rába Vehicle Ltd.

Eligible cost: HUF 792.937,363

Amount of support: HUF 195,741,789

Aid intensity or amount: 25%

Location of the program: 9027 Győr, Martin utca 1 hrsz.: 5454/8

Rába Automotive Components Ltd.

Objective of aid: Restructuring of the production process at the Mór site of Rába Automotive Components Ltd.

Eligible cost: HUF 1,065,985,283

Amount of support: HUF 372,394,849

Aid intensity or amount: 25%

Location of the program: 8060 Mór, Ipartelep hrsz.:0243/6

ERNYO_13-1-2013-0017

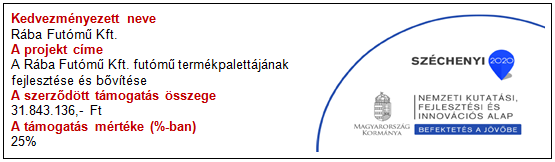

Development and expansion of the product range of Rába Futómű Kft.

In 2013, Rába Futómű Kft. submitted a successful application to the National Research, Development and Innovation Fund. With the nearly HUF 32 million non-refundable subsidy won in this way, it was possible to develop and expand the company's chassis product range.

The company launched a development program with the support of the National Research, Development and Innovation Fund within the framework of the project "Development and expansion of the chassis product range of Rába Futómű Kft.". The investment took place between 2013 and 2016.

Within the framework of the project with a total value of nearly HUF 130 million, commercial vehicle undercarriages and undercarriage-related components (such as wheel loading systems) were developed for agricultural and other applications, thus expanding the company's product portfolio and supplementing the products already in production.

In the program, the employees of the company, on the one hand, have a so-called a rotary sealing system (CTI) has been developed to reduce the ground pressure of vehicles by regulating the tire pressure, thus preventing excessive soil compaction during agricultural work.

In addition, a multi-stage drive unit has been developed that is typically used in bus applications. Due to the compactness of the engine, an intelligent, pressurized lubrication system has also been created.

With all these developments, Rába entered new areas, as these systems were not previously part of the fund's competencies. The systems implemented during the project, which are closely related to the undercarriages, also contribute to the expansion of the transport content, so that the company is able to meet the diverse, growing needs of the partner companies at a higher level and proactively address the growing market challanges.

—————————————————————————————

GINOP-2.1.6-16-2017-00001

Developemnt of new export-orianted product development technologies at Rába Futómű Kft.

Project ID number: GINOP-2.1.6-16-2017-00001

Beneficiary's name: Rába Futómű Gyártó és Kereskedelmi Kft.

Project title: Development of new export-orianted product development technologies at Rába Futómű Kft.

Amount of support: HUF 303,198,385

Aid intensity or amount: 45,7%

Date pf actual physocal completion of the project: 18.11.2020.

Project presentation:

In the framework of the present project, Rába Futómű Kft. intends to develop a new production technology that makes front axle production more competitive, with which it makes the manufactured product more competitive on the world market in the long run, and with help of which new, exportable products can be developed. The focus of the technological research and development project is Rába's most importan product group, heavy vehicle front axles and chassis parts, and its manufacturing technology. As an expected result of the technological research, Rába Futómű Kft.

—————————————————————————————

GINOP-2.2.1-15-2016-00017

Development of a new commercial vehicle powertrain with higher efficiency, higher performance, lower noise and extended service life.

Project ID number: GINOP-2.2.1-15-2016-00017

Beneficiary's name: Rába Futómű Gyártó és Kereskedelmi Kft.

Consortium members: Bay Zoltán Applied Research Public Benefit Nonprofit Ltd., JANKOVITS ENGINEERING Ltd., University of Miskolc

Project title: Development of a new commercial vehicle powertrain with higher efficiency, higher performance, lower noise and extended service life.

Amount of support: HUF 578,946,410

Aid intensity or amount: 71,42%

Date pf actual physocal completion of the project: 31.03.2021.

Project presentation:

The amount of support obtained within the framework of the application number GINOP 2.2.1-15-2016-00017 created an opportunity for Rába Futómű Kft., as a consortium leader, to develop the know-how of oil lubrication of engines in greater professional depth than before, as well as to develop new solutions, who will be the flagships of your portfolio in the future. In addition to reducing engine losses and thus increasing efficiency, Rába took advantage of the opportunity to develop a new, innovative powertrain lubrication system that takes into account the operating conditions, in addition to the traditional lubrication and cooling solutions used so far in undercarriages. The main goal of the tender, the development of a higher efficiency, higher performance, lower noise level and extended service life, is the driving force and the main guideline for the development of the engine and the development of a new type of "smart" lubrication system. Project implementation time July 1, 2016 - March 31, 2021.

By winning the grant, development opportunities opened up for Rába Futómű Kft., the use of which not only changed the market needs of the current customers, e.g. the noise reduction, the longer service period and the higher efficiency can be satisfied, but it is possible to effectively compete with competing manufacturers, which can strengthen Rába's international market position.

—————————————————————————————

GINOP-6.1.5-17-2018-00178

Employee training at Rába Futómű Kft

Project ID number: GINOP-6.1.5-17-2018-00178

Beneficiary's name: Rába Futómű Gyártó és Kereskedelmi Kft.

Project title: Employee training at Rába Futómű Kft

Amount of support: HUF 43,597,744

Aid intensity or amount: 100%

Date pf actual physocal completion of the project: 26.02.2021.

Project presentation:

In the framework of the project, the target group of the trainings served to train or further train physical staff holding key positions in the industrial production activity, mainly with basic or secondary education or professional qualifications, as well as to strengthen the competencies of white-collar workers in order to increase the efficiency of production. The vast majority of the trainings implemented are OKJ, can be classified into the category of other professional training, which significantly increases the market competitiveness of the employees, in addition, in the category of other training, as well as among the internal trainings, knowledge was acquired that increases the employability of the employees.

Development of basic lubrication system for undercarriages -

research and development project with European Union support at Rába Futómű Kft.

In 2012, Rába Futómű Kft. submitted an application for the Economic Development Operational Program of the New Széchenyi Plan. With the support of the European Union, the company had the opportunity to create intelligent oiling systems.

Rába Futómű Kft. has launched a research and development programme with the support of the European Union in the framework of the project "Development of a basic lubrication system for running gears". The company's GOP application was deemed eligible for funding by the evaluation committee, which awarded almost HUF 215 million in non-refundable grants. The development was implemented between 2012 and 2015.

Launched in the summer of 2012, the main goal of the project was to develop an intelligent lubrication system for high-performance agricultural undercarriages that increases cooling and lubrication efficiency using mechatronic devices. By using such systems, - primarily the so-called by minimizing oil agitation losses -, the mechanical loss of the chassis is reduced, the efficiency of the vehicle is increased, its consumption is improved thus more cost-effective and environmentally friendly operation is realized. Mechatronic systems are able to provide the chassis with extra content that provides significant added value and allows for adaptive oil consumption during operation, resulting in more reliable operation.

During the development, we built a new competitive know-how base. The created system can be used in the development of other products, so not only in the field of agriculture, but also in the field of bus and truck chassis. With the introduction of new simulation methods, we can examine the conformity of products at an early stage of design, thus increasing the efficiency of the entire development process.

Within the framework of the project, our colleagues specialized in the field of mechatronics. In our equipment, we carried out significant new developments, design and testing activities that were necessary for the success ful completion of the project. During the implementation of the research and development program, Rába Futómű Kft. closely cooperated with Bay Zoltán Applied Research Public Benefit Nonprofit Kft. and with several departments of the Budapest University of Technology and Economics.

—————————————————————

Complex technology development at Rába Futómű Kft.

In 2013, Rába Futómű Kft. submitted a successful application within the framework of the Economic Development Operational Program. With the non-refundable support of nearly HUF 625 million won in this way, the company had the opportunity to develop complex technology and expand production capacity.

Rába Futómű Kft. has launched a complex development programme with the support of the European Union in the framework of the project "Technology development and production capacity expansion". The investment, which consists of equipment acquisition, software and real estate development, was implemented between 2013 and 2015.

Within the framework of the project with total value of more than two billion forints, 10 new individual machines were purchased, which effectively support the processes, related to the production of the undercarriage.

Also within the framework of the project, the so-called "clean assembly shop" was built on 8600 square meters in the spare parts assembly plant of Rába Futómű Kft. The works carried out were aimed at the modernisation of the area reserved for assembly activities. As a result, the infrastructure, visual appearance and systems of the site have been renewed.

As a part of the software development module, Rába's corporate governance system, Oracle software, was migrated and customized, which thus more effectivel supports the daily activities of employees. In addition, the new Microsoft licenses acquired have upgraded the company's office applications. New software allows you to work faster, more efficiently, more securely.

Overall, the project, launched in 2013, will contribute to the modernization of production capacities, the acceleration of the process of technology change and the development of infrastructure. Thanks to the implemented developments, the company is able to satisfy the needs of the partner companies with increased capacity, more modern technology and higher standards.

—————————————————————————————————

Complex technology development at Rába Jármű Kft.

In 2013, Rába Jármű Kft., submitted a tender within the framework of the Economic Development Operational Program. With the HUF 395.43 million non-refundable support thus obtained, the company opened up opportunities for complex technology development, production capacity expansion and infrastructure development in the total value of nearly HUF 1.4 billion.

Rába Jármű Kft. has launched a complex development program with the support of the European Union. The application GOP-2.1.3-12-2012-0015 of the company was qualified for support by the evaluation committee. The investment, which consists of asset acquisition, software and infrastructure development elements, was implemented between 2013 and 2015.

As part of the project, in order to increase export sales and create the conditions for the bus program, the company carried out infrastructure development as well as equipment purchases during the relevant pariod.

The 28,000 square meter factory hall of Rába Jármű Kft. has undergone external and internal renovation.

As a result of the investment, a more modern energy-saving, thermally insulted building with modern heating and lighting was created, which meets today's requirements. The investment will enable workers to perform their day-to-day tasks under better working conditions.

As part of the project, the assets of the vehicle business were expanded. The company has the opportunity to purchase machines and equipment that play a significant role in the production of vehicle parts and in the assembly operations of the assembly phase. In addition to the plate technology CNC-controlled laser and plasma cutting machines and robot welding equipment, diagnostic tools were installed in the assemblies. In order to make the logistics more efficient, hall bridge cranes and lifting equipment were purchased, and the development of a warehouse storage system could be started.

As part of the software development module, in addition to special software for operational use, new MS computer licenses were also acquired. New software allows you to work faster, more efficiently, more securely.

The project, launched in 2013, contributes to the modernization of production capacities, the acceleration of the proccess of technology change, and the modernization of plants through the development of technologies, as well as the creation of new jobs.

————————————————————————————————-

Technological development and job creation at Rába Járműipari Alkatrészgyártó Kft. in order to fulfill orders in the automotive industry

The technology development capital expenditure and reorganisation activities of strategic signifi-cance implemented within the New Széchenyi Plan, the Economic Development Operational Program (hereinafter GOP), the National Development Agency published a call for the support of complex technological development and employment, for which Rába Járműipari Alkatrészgyártó Kft. registered under identification number GOP-2.1.3-11-2011-0003, 2011.05.05 submitted an application, which was supported by the Sponsor. Based on the decision of the Sponsor, our company received a non-refundable grant.

Date of conclusion of the contract: 27.07.2011

Number of jobs retained: 759 people

Number of jobs created: 41 people

The main investments implemented within the framework of the Project::

630 T press

Riveting line

Welding machines

Two-arm spot welding robot

Machining Center

Lathes

Construction of a warehouse